As one of the professional automotive plastic injection molding companies in China, Keyplast provides quality one-stop injection moulding automotive solutions for our customers. Many customers from the automotive industry approach Keyplast to solve their own automotive injection molding challenges, from prototypes, engineering validation testing, design validation testing, production validation testing, and mass production.

Ford is one example that engaged with Keyplast, a professional automotive injection molding company, to move forward with its project of injection moulding automotive parts. Our cooperation started with rapid prototypes with different 3D-printing technologies, to check the appearance and assembly through 3D prints. Then we moved into validation testing of engineering, design, and production. During the testing process of automotive injection molding, we removed some unnecessary angles, improved some injection molding automotive parts, and accelerated the design. For the managing team of Ford, Keyplast insisted that quality always came as the first priority. And the key factor for them when choosing a supplier was to get the best quality in the project. As a new product, Ford requested the initial batch for the first month of only 50 units, for the second month 100 units, and then 500 units for the next month. Keyplast could provide the low-volume quantity repeatably and continually but also ensure the quality and speed.

Today, Keyplast and Ford have established a long-term supply chain and benefited mutually. As a reliable China plastic injection parts supplier, Keyplast offers quick responses to the injection molding automotive parts and injection mold design engineering requests from Ford, and Ford keeps a small amount of inventory, optimizes cash flow, and gets a great competitive advantage in the market.

Interior Parts:

Dashboard Panels: Provides structural support and houses various instruments and controls.

Door Handles: Durable and ergonomic parts for interior and exterior access.

Air Vents: Facilitates airflow and climate control within the vehicle.

Instrument Clusters: Encloses the speedometer, tachometer, and other vital gauges.

Exterior Parts:

Bumpers: Protects the vehicle's front and rear from impacts.

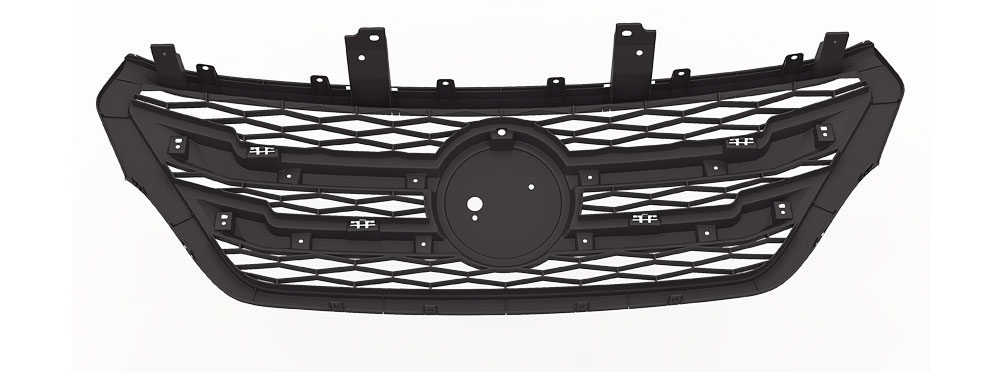

Grilles: Allows air intake and protects the radiator.

Lighting Components: Headlamp and taillight housings that require high precision and clarity.

Engine Components:

Engine Covers: Provides protection and aesthetic appeal to the engine bay.

Air Intake Manifolds: Manages airflow into the engine for optimal performance.

Reservoir Tanks: Stores fluids like coolant and windshield washer fluid.

Functional Parts:

Clips and Fasteners: Essential for assembling various parts of the vehicle securely.

Brackets: Supports and mounts different components within the car.

Gaskets and Seals: Ensures airtight and watertight connections between parts.

Polypropylene (PP):

Properties: Lightweight, chemical resistant, and good fatigue resistance.

Applications: Used in both interior and exterior parts such as bumpers, dashboard panels, and fluid containers.

Acrylonitrile Butadiene Styrene (ABS):

Properties: High impact resistance, good surface finish, and rigidity.

Applications: Ideal for interior components like dashboard parts, instrument panels, and trim.

Polyamide (Nylon):

Properties: High strength, excellent thermal resistance, and good wear resistance.

Applications: Suitable for under-the-hood components such as engine covers, air intake manifolds, and various mechanical parts.

Polycarbonate (PC):

Properties: High impact strength, clarity, and good thermal stability.

Applications: Used in lighting components, lenses, and other transparent parts.

Polyoxymethylene (POM):

Properties: High stiffness, low friction, and excellent dimensional stability.

Applications: Utilized in precision parts such as gears, clips, and fasteners.

Polyurethane (PU):

Properties: Flexible, durable, and provides good cushioning.

Applications: Often used in seating, insulation, and gaskets.

Thermoplastic Elastomers (TPE):

Properties: Combines the properties of rubber and plastic, providing flexibility and resilience.

Applications: Used for seals, gaskets, and flexible connectors.

Conceptual Design: Engineers create a detailed design of the part, considering factors like material selection, functionality, and aesthetics.

3D Modeling: Using CAD software, a 3D model of the component is developed.

Prototyping: A prototype is created, often using 3D printing or other rapid prototyping methods, to validate the design and make necessary adjustments.

Mold Design: Based on the final part design, a detailed mold design is created. This includes considerations for mold flow, cooling channels, and ejection mechanisms.

Mold Fabrication: Skilled toolmakers manufacture the mold using high-precision machining techniques. The mold typically consists of two halves – the core and the cavity.

Mold Testing: The mold is tested with initial trial runs to ensure it produces parts accurately and efficiently.

Mold Setup: The mold is mounted on the injection molding machine, and the two halves are securely clamped together.

Machine Calibration: The machine settings are calibrated to control temperature, pressure, and injection speed based on the specific material and part requirements.

Plastic Melting: Plastic pellets are fed into the machine’s hopper and heated to a molten state in the barrel.

Injection: The molten plastic is injected into the mold cavity through a nozzle under high pressure, ensuring it fills all the intricate details of the mold.

Pressure Holding: The machine maintains pressure to compensate for material shrinkage as the plastic begins to cool and solidify.

Cooling Time: The mold is kept closed while the plastic cools and solidifies. Cooling channels within the mold help regulate the temperature and speed up the cooling process.

Solidification: The part takes shape and achieves its final properties as it cools.

Mold Opening: The clamping unit opens the mold.

Part Ejection: Ejector pins or plates push the solidified part out of the mold cavity. Care is taken to ensure the part is removed without damage.

Trimming: Excess material, such as sprues and flash, is trimmed off the part.

Finishing: Depending on the application, the part may undergo additional finishing processes such as painting, coating, or assembly.

Quality Control: The parts are inspected for defects and dimensional accuracy to ensure they meet the required standards.