Plastic turnover boxes are frequently used in production and everyday life. By using different types of plastic turnover boxes, ranging from the shelves used to display fruits in grocery stores to beer and soda bottle crates used in the food industry, and storage boxes used in logistics and transportation, they have found widespread application in many industries due to their durability, lightweight nature, and efficient storage and transportation capabilities.

Turnover Box Plastic Moulds: Essential Tools for Injection Molding

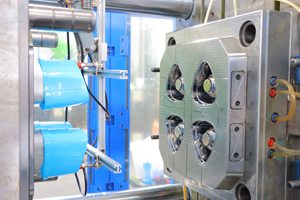

Typically, plastic containers are produced using injection molding, which involves compressing plastic granules into molds with an injection molding machine, and after cooling, the complete plastic container is obtained. Injection molding is a common method for producing plastic turnover boxes, particularly in large-scale production where efficiency and precision are crucial. Through injection molding, molds can rapidly and efficiently produce various specifications of plastic turnover boxes to meet the needs of different fields.

When liquid plastic fills the mold cavity and core, it takes on the shape of the turnover box. Different plastic box molds can be used to manufacture various shapes and sizes of packaging boxes, such as Coca-Cola plastic bottle crates, vegetable boxes, fruit boxes, seafood transport boxes, bakery turnover boxes, milk crates, industrial turnover boxes, folding boxes, thin-walled parts boxes, double-walled crates, and boxes that can be stacked on both sides. Turnover box plastic moulding supplies need to be designed according to different specifications and customized based on the characteristics of the industry in which they are used.

Basic Conditions for Quality Turnover Box Plastic Moulds

High-quality mold steel (appropriate type of steel and hardness) can be used to extend the mold's lifespan.

Easy injection molding (sometimes requiring special designs for the hot runner system, such as filters, etc.), making it more suitable for producing recyclable containers.

Optimal cooling water channel design.

Excellent exhaust system design.

Interchangeable mold design (to achieve turnover box diversification and reduce mold costs).

Advanced demolding system.

Necessary Mechanical Equipment: Plastic Turnover Box Injection Molding Machine.

Apart from plastic turnover box moulds, the accompanying injection molding machine is also indispensable. In a plastic turnover box injection machine, raw plastic granules undergo a series of processes to ultimately produce the finished turnover box, which is then demolded to obtain the turnover box. The quality of the injection molding machine directly influences the production efficiency and final quality of the plastic turnover box, making the selection of a suitable injection molding machine crucial.

In summary, turnover box plastic moulds and injection molding machines are two key factors in the production of plastic turnover boxes. Only by combining high-quality molds and equipment can high-quality, efficient turnover boxes be produced. Ensuring excellent mold design and superior injection machine performance is fundamental to guaranteeing the quality of plastic turnover boxes during the production process.