The size of the mold can be determined based on the size of the product plus the shrinkage rate, so the main factor to consider in mold design is the shrinkage rate. The shrinkage effect varies depending on the resin and molding conditions.

Resin pressure greatly affects the shrinkage rate. If the resin pressure is high, the shrinkage rate becomes smaller and the product size becomes larger. Even in the same cavity, the resin pressure can vary depending on the shape of the product. In the case of multi-cavity molds, the resin pressure in each cavity may be different, and the shrinkage rate in each cavity may also be different.

Whether it is an amorphous resin or a crystalline resin, if the mold temperature is high, the shrinkage rate increases. The mold temperature should be kept at a specific temperature during injection molding.

Usually, when the cross-sectional area changes, the shrinkage rate also changes. As the gate size increases, the shrinkage rate decreases, which is related to the resin flowability.

The thickness of the custom injection molding also affects shrinkage. For amorphous resins, the resin often has different effects on the shrinkage rate of the wall thickness. The larger the wall thickness, the larger the shrinkage rate. Conversely, the smaller the shrinkage rate. For crystalline resins, it is necessary to avoid significant changes in wall thickness. In the case of multi-cavity molds, if the wall thickness of the cavities is different, the shrinkage rate will also change.

When using fiber-reinforced resin, the more glass fiber added, the smaller the shrinkage rate. The shrinkage rate in the flow direction is smaller than that in the transverse direction. To prevent distortion and warpage, the shape, position, injection moulding raw material list and number of gates must be considered.

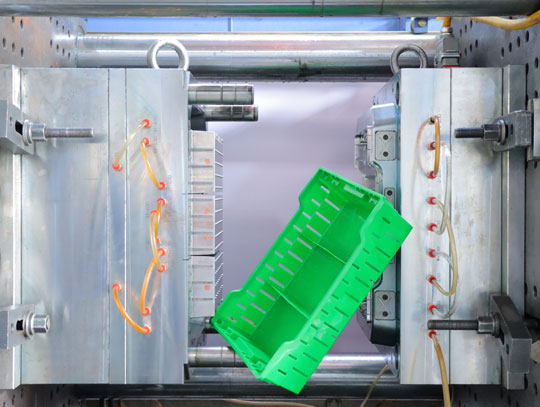

The production of injection moulding process products is closely related to the injection molding molds, so the working status of the injection molding molds is of vital importance to the quality of the injection molding products. The molds create value during use, but they also gradually lose their value during the process. Therefore, operators must attach great importance to the use of injection molding molds and pay attention to the following points.

Before use, check whether there are impurities or dirt on all parts of the injection moulding mold. For plastic molding materials and impurities remaining in the mold, use cotton yarn to scrub and remove the adhesive.

Choose the clamping force reasonably to avoid burrs during product molding. The higher the clamping force, the easier it is for the transmission parts to be damaged.

Each drive part should be well lubricated, so the injection molding mold parts must be kept lubricated.

It is not allowed to use heavy objects to strike any part of the mold to avoid the deformation or even damage of the mold.