Injection molding materials for injection molding process conditions

The complexity of injection material properties often determines the complexity of the injection molding process. Under normal circumstances, the complexity of the material is not what we want. The performance of injection molding materials varies greatly due to different varieties, different brands, different manufacturers of injection molding parts, and even different batches. Therefore, it is necessary to make corresponding adjustments according to the properties of the material. Different performance parameters can lead to completely different molding results.

Injection temperature of injection molding process conditions

This is an important one. The melt flows into the cooled cavity, dissipating heat by conduction. A certain amount of heat loss occurs. At the same time, heat is generated due to shearing, and this part of the heat may be more or less than the heat lost by thermal conduction, depending on the conditions of the injection molded parts. This also causes some heat to be lost. The viscosity of the melt decreases with increasing temperature. Thus, the higher the injection temperature, the lower the viscosity of the melt and the lower the required filling pressure. At the same time, the injection molding temperature is also limited by the thermal degradation temperature and decomposition temperature. This restriction causes temperature changes.

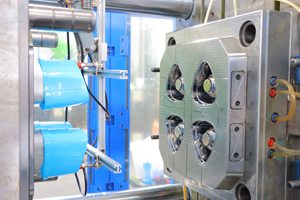

The temperature of the injection mold in the injection molding process

Is the higher the mold temperature the better or the lower the better? The lower the mold temperature of the injection part, the faster the heat dissipation due to heat conduction, the lower the melt temperature and the poorer the fluidity. The temperature also affects the speed of fluidity. This phenomenon is especially pronounced when lower injection rates are used.

Injection time of injection molding process conditions

The length of time has a certain impact on the injection molding industry. The influence of injection time on the injection molding product process is manifested in three aspects: shortening the injection time, the shear strain rate in the melt will also increase, so the injection pressure required to fill the cavity should also increase; shortening the injection time, the melt Due to the shear-thinning properties of the plastic melt, the viscosity of the melt is reduced, and the injection pressure required to fill the cavity is also reduced. This is just the opposite of the first point; when the injection time is shortened, the shear strain rate in the melt increases, the shear heating increases, and at the same time, less heat is lost due to heat conduction, so the higher the temperature of the melt, the lower the viscosity. The injection pressure required for the cavity is also reduced.

As a result of the combined effect of the above three conditions, the curve of the injection pressure required to fill the cavity presents a "U" shape. That is, there is an injection time when the required injection pressure is minimal. This is how injection time affects the injection molding process.

The effect of injection molding process conditions on the product is described above. Injection molding has a certain special significance for injection molding materials, injection temperature, mold temperature, and injection time. The injection molding material determines the complexity of injection molding. The injection temperature causes the viscosity to be high or low. The difference in fluidity is caused by the temperature of the mold. The injection time is different, and the injection pressure is also different.