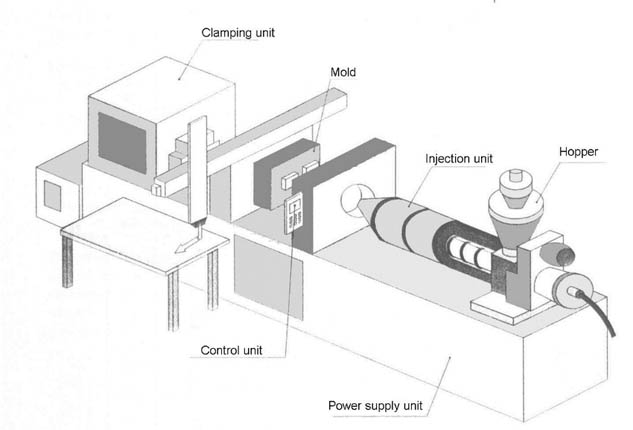

Injection moulding is a manufacturing process that involves melting plastic pellets and injecting the molten material into a precisely machined mold. From small consumer items to large industrial components, this process is widely used in the production of a wide range of products. Injection molding machines can be highly automated, providing a cost-effective solution for high-volume production that can be customized to suit the specific needs of a particular product or industry. This versatile and reliable technique is perfect for mass production of products for industries like automotive, medical, and consumer goods.

As a professional technique, injection molding is utilized to create a diverse range of plastic goods. This technique involves injecting melted plastic into cavities made by molds to produce plastic products of various shapes. In the injection moulding process, there are usually four stages.

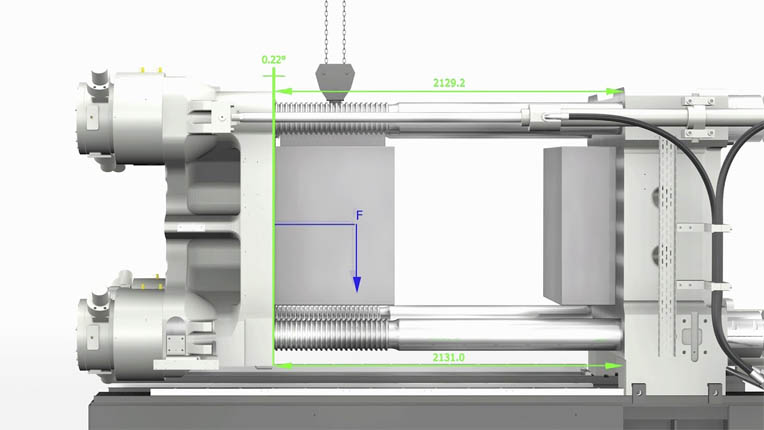

To ensure a successful injection process, sufficient material must be injected into a tightly closed mold. The clamping unit of the injection machine applies the necessary pressure to hold the mold firmly closed while injecting the material to ensure complete filling. The size of the injection machine affects the time required for mold closing and clamping, and generally, larger machines usually require more time to achieve optimal quality and accuracy.

Clamping Unit

During the injection stage of the injection molding process, the raw plastic material, usually in the form of pellets, is fed into the injection machine and pushed towards the mold by the injection system. In this process, the material is heated and pressurized to melt it. Then, the molten plastic is injected rapidly into the mold, while pressure is accumulated and maintained to pack the material. The injection time depends on the type and size of the mold, as well as the composite material being injected. Injection pressure and speed are controlled by the hydraulic system of the injection machine.

Cooling kicks off right after the molten plastic meets the interior surfaces of the mold. This internal cooling process is critical and determines the required cooling time. Through internal cooling, the plastic gradually cools and solidifies into the desired part shape. However, with the decrease in temperature, some areas may experience shrinkage. To minimize this, additional material can be added during the injection stage to reduce visible shrinkage. To ensure quality and reduce defects, the mold must remain closed until the required cooling time is reached, minimizing defects and ensuring proper solidification.

Hot Runner

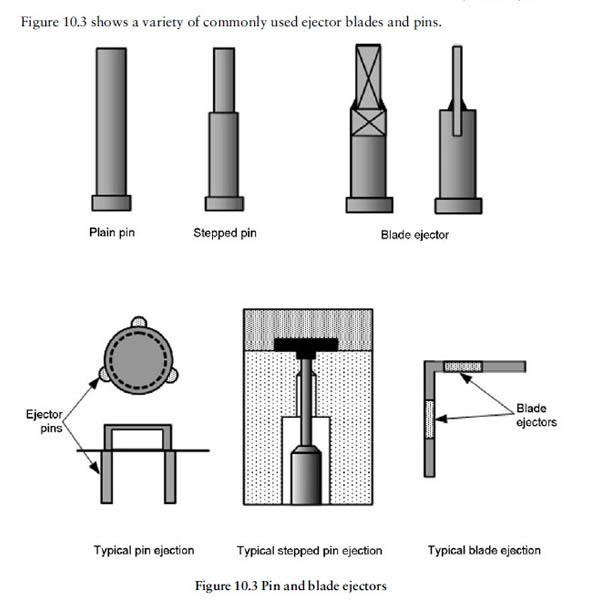

At the final stage, the cooled parts are pushed out by a pop-up system connected to the back of the machine, which utilizes the pop-out mechanism inside the back part of the mold to eject the parts. However, since the parts tend to shrink and adhere to the mold during the cooling phase, considerable force is required. To make demolding easier, the mold cavity surface can be coated with a release agent beforehand to prevent damage to the parts when they exit the mold. Once the parts are successfully ejected, the mold can be clamped again to restart the injection process.

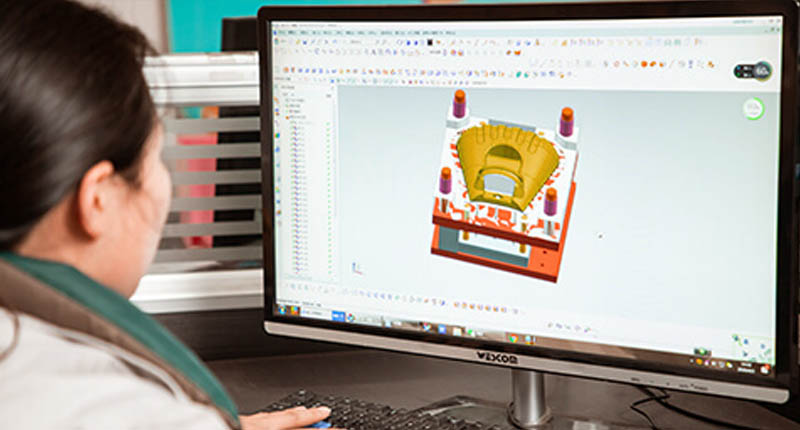

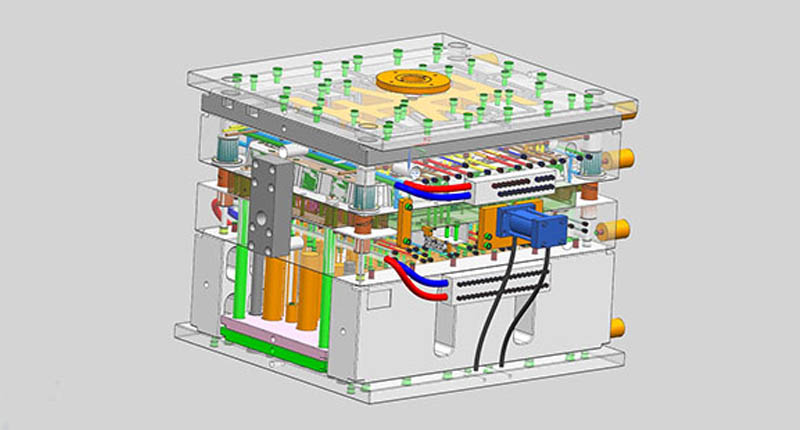

For injection molding supplies, designing an injection mold is a complex process that requires a deep understanding of the material properties of the plastic, the geometry of the part, and the capabilities of the injection molding machine. An injection mold is typically made up of two halves that come together to form the shape of the part. Here are some key considerations and features involved in injection mold design:

Injection Mold Design

Part Design: The first step in mold design is understanding the part that will be produced. This includes its size, shape, and function, as well as the type of plastic that will be used. The part design will determine many aspects of the mold design, including the number of cavities, the layout of the cooling channels, and the ejection mechanism.

Number of Cavities: An injection mold can have a single cavity or multiple cavities. A single-cavity mold produces one part per cycle, while a multi-cavity mold produces multiple parts per cycle. The choice between a single-cavity and multi-cavity mold depends on factors such as the size of the part, the production volume, and the cost.

Runner System: The runner system is the channel that guides the molten plastic from the injection unit of the machine into the cavities of the mold. It typically includes a sprue (the channel from the nozzle of the machine to the runners), runners (the channels that distribute the plastic to each cavity), and gates (the point where the plastic enters the cavity).

Cooling System: To ensure that the part cools and solidifies evenly and quickly, cooling channels are integrated into the mold. These channels carry a cooling fluid (usually water) that removes heat from the mold. The layout of the cooling channels is a critical aspect of mold design because it affects the quality of the part and the cycle time of the molding process.

Cooling system

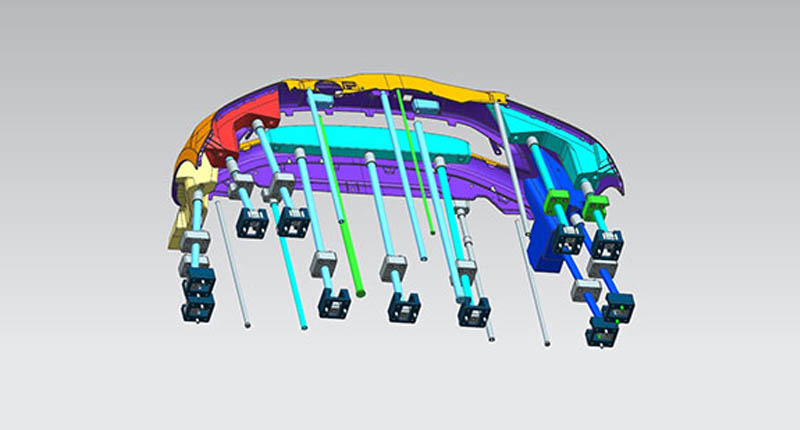

Ejection System: Once the part has cooled and solidified, it needs to be ejected from the mold. The ejection system typically includes ejector pins that push the part out of the mold. The location and number of ejector pins must be carefully planned to ensure that the part is ejected smoothly without being damaged.

Ejection System Design

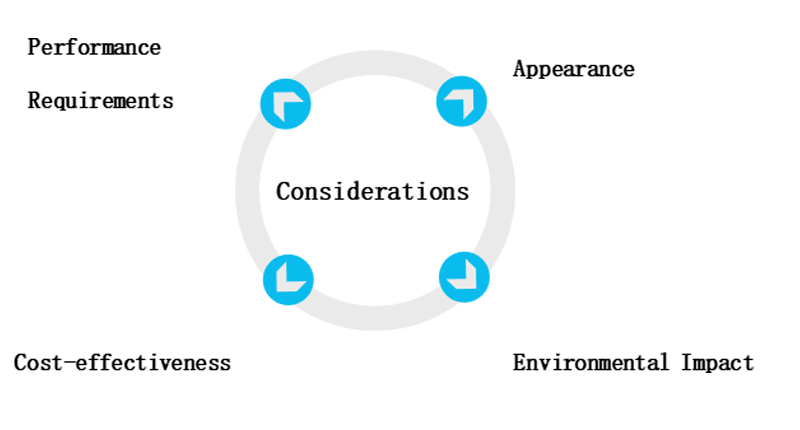

Choosing the right injection molding raw material is a critical decision that affects the quality, functionality, and cost-effectiveness of the produced parts. When selecting materials for injection molding projects, several factors should be considered:

Performance Requirements: The chosen material must fulfill the demands of the product's application. This includes parameters like strength, flexibility, rigidity, heat resistance, impact resistance, and chemical resistance. For instance, if the product must withstand high temperatures, materials like polyphenylene sulfide (PPS) or polyether ether ketone (PEEK) might be suitable.

Appearance: The appearance of a product is one of the key factors that affects its sales. When considering the appearance of a product, various aspects such as the texture of the materials, color coordination, and surface treatment should be taken into account. At the same time, different materials can be treated in different ways to achieve the best results.

Cost-effectiveness: Material costs significantly impact the overall project budget. While high-performance materials like PEEK offer superior properties, they are more expensive than more common plastics like polyethylene or polypropylene. A balance must be found between material cost and performance requirements.

Environmental Impact: The environmental impact of the material, both in terms of its production and its end-of-life disposal or recycling, is an increasingly important consideration. Some plastics are more recyclable than others, and some have a lower carbon footprint in terms of their production.

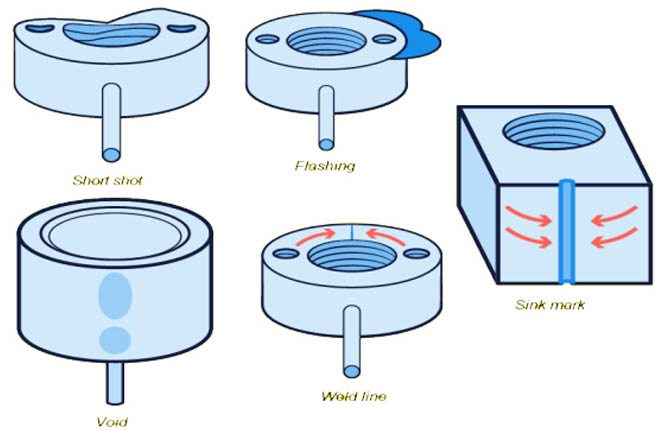

Tips for troubleshooting common issues with injection moulding

During the injection molding process, solving issues related to it becomes a complex task due to the involvement of multiple variables. Here are some common problems and potential solutions:

Short Shot: This occurs when a shot of resin doesn't completely fill the mold cavity, resulting in an incomplete part. This can be caused by an insufficient amount of material, incorrect injection speed or pressure, or a blockage in the mold. To avoid it, consider increasing the shot volume or injection speed, examining the mold for blockages, and ensuring the material is at the right temperature.

Flashing: Flashing is excess plastic that forms along the parting line of the mold or around ejector pins. This can occur if the mold is not clamped tightly enough or if the injection pressure is too high. Solutions include increasing the clamping force, reducing the injection pressure, or checking the mold for wear and tear.

Warping: Warping refers to the deformation that occurs in a part after it is removed from the mold. This may be due to uneven cooling, insufficient holding pressure, or unbalanced part design. Solutions may include optimizing the cooling system, adjusting the holding pressure, or considering a redesign of the part to make it more balanced.

Selecting the right injection molding supply company requires thoughtful consideration of several factors. To ensure top-notch products and services, prioritize experience and reputation. A manufacturer with years of experience and a positive reputation will deliver results you can trust. Production capacity and equipment matter, too. Choose a manufacturer that can meet your volume and equipment requirements, and rest assured that your orders will be delivered on time. Also, verify their quality assurance and after-sales support.

Keyplast is one of the leading injection molding manufacturer located in Huangyan, Zhejiang province China ,have more than 10 years experience in injection molding industry.Meanwhile, we have an efficient team and precise processing and testing equipment, which can provide customized product services for customers.

In conclusion, injection molding is a complex manufacturing process that involves many key steps and technical details. In the main steps of injection molding, clamping, injection, cooling, and ejection are the four key elements, each of which requires precise control and adjustment. In this process, the design of the injection mold is a very important aspect because it directly affects the quality and shape of the molded part. In addition, the selection of injection molding materials is also a crucial issue because different materials have different properties and characteristics that need to be selected based on specific circumstances. At the same time, solving common problems in injection molding is also an essential part of the manufacturing process, such as defects, bubbles, and deformation. Therefore, injection molding requires attention to detail in every step to obtain high-quality molded parts.