In the field of plastic processing, double-shot moulding technology offers an efficient solution for producing two-color or mixed-color plastic products due to its unique advantages. Two-shot molding primarily utilizes double-shot moulding machines, which complete the double-shot moulding process sequentially by precisely coordinating its two barrels and two sets of molds. This results in impressive two-shot products. This article will delve into several key considerations during the double-shot moulding process to ensure smooth production and enhance product quality.

Precise Matching of Double-Shot Moulding Machines and Molds

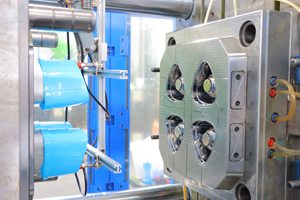

The core of double-shot moulding lies in the precise coordination between the double-shot moulding machine and the two sets of molds. In the preparation stage, it is crucial to ensure that the two barrels can precisely control the key parameters such as the plasticizing temperature, injection pressure, and melt volume for different colored materials, and that these parameters remain consistent across the two devices to minimize fluctuations. Additionally, mold design is critical and must incorporate rotation or repositioning capabilities to meet the different requirements of the two injections, ensuring the optimal two-color or mixed-color effect.

Precise Control of Melt Temperature and Injection Pressure

Compared to regular injection molding, double-shot moulding has stricter requirements for melt temperature and injection pressure. Due to the longer and more complex mold flow channels in two-color injection molding, melt flow resistance increases, necessitating higher melt temperatures and injection pressures. Operators need to closely monitor these parameters during production and adjust them promptly to ensure smooth melt flow and adequate bonding, thereby avoiding product defects.

Material Selection and Melt Stability

The choice of materials directly impacts the quality of two-shot molded products made by the injection molding supply company. To ensure the stability and quality of two-color plastic products during molding, materials with good thermal stability and low melt viscosity should be selected. These materials are less likely to decompose at high temperatures and can maintain stability in the flow channels for extended periods. Polyolefin resins, polystyrene, and ABS materials are commonly used in double-shot moulding due to their excellent performance.

Optimization of Injection Rate and Mold Temperature

In the double-shot moulding process, the injection rate and mold temperature are also key factors to focus on. A higher injection rate helps the melt quickly fill the mold cavity, reducing the occurrence of bubbles and shrinkage. At the same time, appropriately increasing the mold temperature can accelerate the cooling speed of the melt, promote the bonding of the two colored melts, and improve the overall strength and appearance quality of the product. Therefore, during production, the injection rate and mold temperature should be adjusted reasonably based on the specific product requirements and mold characteristics.

Detail Control During the Molding Process

In addition to the above points, detail control during the double-shot moulding process is also crucial. For instance, after the first injection, ensuring the accurate rotation or repositioning of the mold is necessary to avoid affecting the second injection's outcome. Additionally, it is important to regularly check the wear and tear of nozzles and cores, replacing damaged components promptly to ensure precise injection. A clean and tidy production site is also essential to guarantee product quality.

In conclusion, although double-shot moulding technology has significant advantages, multiple aspects of detail need attention during actual production. By precisely matching equipment and molds, finely controlling process parameters, reasonably selecting materials, and strictly managing various stages of the molding process, the potential of double-shot moulding technology can be maximized to produce high-quality two-color or mixed-color plastic products.