The turnover box is mainly used to transport various products, so it is also called the logistics box.

According to the different products to be transported, the turnover boxes mainly include the following categories: fruit turnover boxes, fish turnover boxes, industrial product turnover boxes, bottle turnover boxes, bread turnover boxes, etc.,

The two shot molding design guide of turnover boxes for different purposes needs to consider details such as shape design, superposition effect, load-bearing strength and production cost.

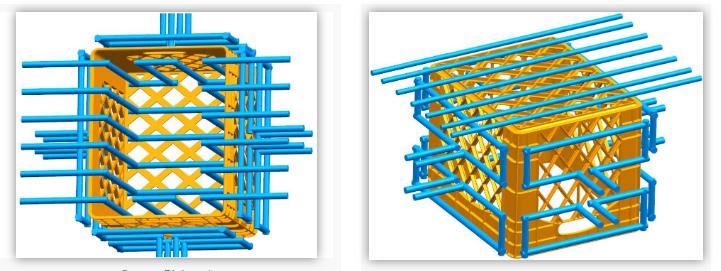

Below are some crates we made for reference.

1) Design of cooling water circuit

The cooling of the turnover box mold is very important. Reasonable cooling can reduce the deformation of the product and shorten the injection molding cycle.

The size of the diameter of the waterway and the uniform distance of the arrangement need to be precise.

The diameter of the water channel is too small and the cooling is not timely, resulting in excessive mold temperature and resulting in deformation of the product, thereby increasing the production cycle of the product and reducing the production efficiency.

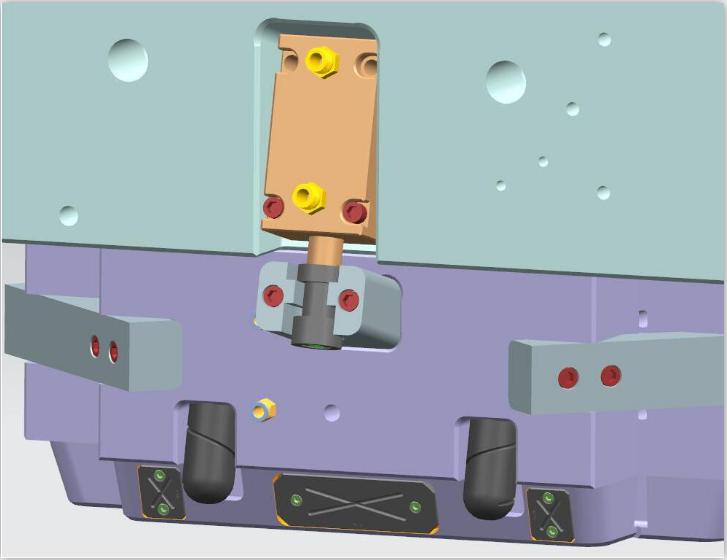

2) The slider core pulling and ejecting system of the turnover box mold

1. Slide core pulling

Most of the structure of the turnover box mold are fixed mold four-slide core pulling, this injection mold design engineering can make the surrounding of the turnover box smoothly draw out without scratching the surface of the product, and can also control the size of the mold, thereby reducing the cost of the mold.

2. Ejection system

The turnover box mold is usually ejected by the top plate. According to the actual situation, the design of the ejector system should be as simple as possible to reduce the probability of failure.

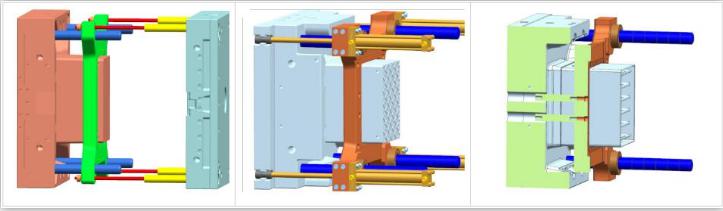

3) Gate design

For the gate design of the turnover box mold, we can choose either hot runner or cold runner.

Cold runners are recommended if return material will be added to the plastic material. The large gate is placed in the center of the bottom of the turnover box to avoid gate blockage.

If the turnover box is produced with new injection molding materials, it is recommended to choose multiple hot runners, which can not only reduce the excess runner waste, but also reduce the process of shearing the runner gate.

For the number of points of the hot runner, it is generally 2, 4, 6 or more points into the gate, which is finally selected according to the structural design and weight of the product.

3. Selection of mold steel

The steel of the turnover box mold is generally P20, 718, and 2738, which are more cost-effective.

The steel used for different mold parts of the turnover box mold is also different, and the steel needs to be selected according to the cost budget of the mold.

4. The requirements of processing equipment

The processing accuracy of the turnover box mold is not low, especially in the processing of the core, the cavity, the four-slider and the stripper plate, which requires good equipment processing to make the assembly easier and avoid flash and scratches.

5. The production experience of turnover box mold

As a professional plastic injection mold maker in china, Keyplast has made hundreds of turnover box molds. Keyplast has very sufficient experience in product design advice, mold design review, mold processing control, and comparison and inspection between samples and designs.

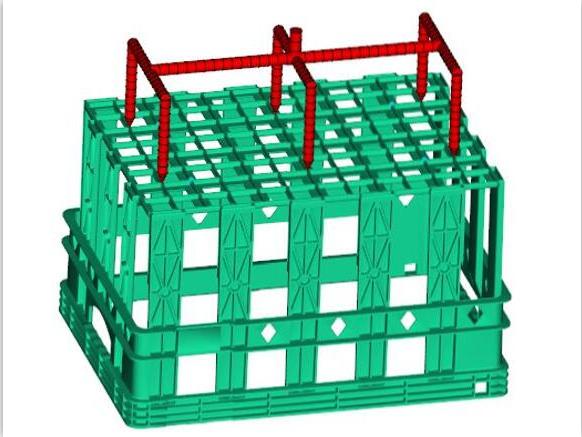

Below are some of the crate moulds we made by Keyplast.

6. The price of turnover box mold

The injection moulding price depends on the size of the product, the choice of steel, and the brand of the hot runner.

Taking a turnover box of 490x350x300mm and weighing 1600g as an example, the size of the mold is about 880x750x720mm, the weight is about 3250kg, and the required injection molding machine model is 600-800T.