In the fiercely competitive world of manufacturing, producing products that stand out in terms of design and durability is essential for success. One technology that has emerged as a game-changer in this regard is "Double Shot Moulding." This innovative process allows manufacturers to create unique and visually appealing products by combining two different materials or colors in a single mold. In this blog, we will explore the numerous benefits of double shot moulding, from enhanced aesthetics to improved durability, and how it has revolutionized the way products are conceptualized and brought to life.

Unleashing Creativity with Unique Designs

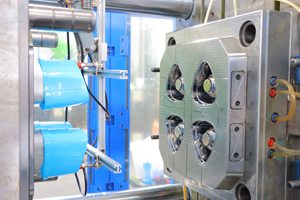

Double shot moulding enables the seamless integration of two different materials within a single product. This means manufacturers can combine materials with distinct properties, such as hard and soft plastics, to create products with innovative designs and enhanced functionality. This opens up a world of creative possibilities, allowing designers to envision products that were previously limited by traditional manufacturing techniques. With double shot moulding, adding a splash of color to products becomes a breeze. By injecting different colors into the same mold, manufacturers can create eye-catching patterns and designs that captivate consumers' attention. Whether it's vibrant smartphone casings or colorful automotive interiors, the ability to use multiple colors elevates the aesthetics of the final product.

Enhanced Product Durability

One of the most significant advantages of double shot moulding is the strong bond between the two materials. This bonding process creates a robust and reliable final product, making it highly resistant to mechanical stress and wear. Consequently, products manufactured through double shot moulding tend to have a longer lifespan compared to those produced by traditional methods. By combining multiple components in a single manufacturing cycle, double shot moulding eliminates the need for additional assembly steps. This reduction in assembly requirements not only streamlines the production process but also results in products with fewer potential weak points or points of failure, contributing to their overall durability.

Cost-Effectiveness and Efficiency

Double shot moulding simplifies the manufacturing process by incorporating multiple components into a single mold. This reduction in complexity leads to faster production cycles, reduced material wastage, and lower labor costs. As a result, manufacturers can achieve cost-effectiveness without compromising on product quality. With double shot moulding, manufacturers can create multi-material products using a single injection moulding machine. This eliminates the need for investing in separate machinery for each material, further reducing capital expenditure and operational costs.

Versatility Across Industries

The automotive industry has embraced double shot moulding for producing aesthetically pleasing and durable components. From sophisticated dashboard panels with contrasting colors to ergonomic steering wheel grips, this process has elevated the interior and exterior design possibilities in the automotive sector. In the electronics and consumer goods industries, manufacturers leverage double shot moulding to create products that are both functional and visually attractive. This includes items such as remote controls, computer peripherals, and personal electronic devices, where combining different materials and colors enhances the user experience. The medical sector benefits from double shot moulding's ability to produce medical devices with intricate designs and superior durability. By using biocompatible materials in conjunction with other functional polymers, manufacturers can develop safe and reliable medical products.

Double shot moulding has redefined the possibilities in modern manufacturing, offering unique designs, enhanced durability, and cost-effectiveness across various industries. The ability to seamlessly integrate different materials and colors in a single production cycle empowers designers to create products that captivate consumers' imaginations. With its myriad of benefits and versatility, double shot moulding continues to be a driving force behind the production of exceptional and durable products that leave a lasting impact on the market.