In the injection molding process, the injection molding surface finish is an important indicator of product quality. It not only concerns the aesthetics of the product but also directly affects the durability and functionality. So, what factors influence the injection molding surface finish? This article will delve into aspects such as material selection, mold design, injection temperature, and speed.

Material Selection

The primary factor affecting the injection molding surface finish is the material used. Each material, due to its unique physical and chemical properties, has a different impact on the final product's surface smoothness. The melting temperature of the material is a key parameter as it directly relates to the flowability of the melt in the mold and the surface condition after cooling. For products that require a glossy finish, increasing the melt temperature when using crystalline resin materials is an effective way to reduce surface roughness and enhance glossiness.

Additionally, additives in the material play an important role. Suitable additives can significantly improve the processing performance and surface characteristics of the material. For example, lubricants can reduce friction between the melt and the mold, thereby decreasing scratches and mold marks. However, it is worth noting that relying solely on polishing the mold surface to enhance glossiness is simplistic, as mold design, molding conditions, and the intrinsic properties of the materials collectively influence the final smoothness.

Mold Design

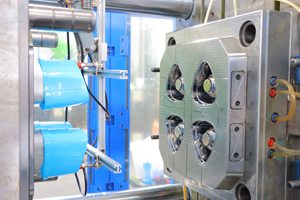

The injection mould design is equally crucial to surface smoothness. The core design of the mold must be meticulously planned to ensure that the melt flows uniformly during the filling process, avoiding defects like bubbles and sink marks. The design of the mold's runners, venting systems, and the proper configuration of the cooling systems are key factors in improving surface smoothness.

Moreover, the material of the mold is another important factor affecting surface quality. High-quality mold steel not only has high hardness but also can maintain stable dimensional accuracy and surface quality over long-term use. Choosing a mold material that suits the characteristics of the material being molded can effectively reduce mold wear, enhance the surface smoothness of the product, and maintain production stability.

Injection Temperature and Speed

The injection speed and temperature of the molten material are another set of important parameters affecting the plastic injection molding surface finish. The selection of injection speed must be based on the flowability of the material and the mold design. Rapidly filling the mold cavity can reduce the visibility of weld lines and also help improve surface smoothness and overall appearance. However, excessive injection speed may lead to shear heating of the melt, affecting the crystallinity and surface quality of the material.

At the same time, injection temperature is an essential factor. Appropriately increasing the injection temperature and mold temperature helps reduce the viscosity of the melt, improving its flowability and making it easier to achieve a smooth surface. However, excessively high temperatures may cause material degradation or scorching, affecting product quality and safety.

In summary, the injection molding surface finish is influenced by multiple factors such as material selection, mold design, and injection temperature and speed. In actual production, these factors need to be considered comprehensively. By precisely controlling and continuously optimizing process parameters, the surface smoothness and overall quality of products can be improved.